Blauberg Turbo EC 250

EAN4058448046711

EAN4058448046711 - Description

- Characteristics

- Capacity diagram

- Downloads

- Dimensions

- Additional characteristics

- Designation key

- Accessories

| USE | SPEED CONTROL |

|

Designed for supply and exhaust ventilation systems requiring high energy efficiency, excellent response, high pressure and air flow rate while keeping noise under control – such as high-humidity commercial and industrial spaces (e.g.bathrooms and kitchens) as well as flats, villas, shops and cafes. Compatible with air ducts from 100 to 315 mm in diameter. |

The fan speed is controlled with a 0–10 V control signal from the following sources:

The control signal value changes depending on air temperature, pressure, smoke concentration and other parameters.During signal value change the fan with EC motor correspondingly changes the rotations speed and delivers required air volume to the ventilation system.The computer central building management systems (BMS) enable integration of several EC motors in network and precise individual operation control for each fan. |

| DESIGN | |

|

Turbo EC fans combine the versatility and outstanding performance of both axial and centrifugal fans producing a powerful air flow and high pressure while retaining the signature energy-efficiency and response of EC motors.The casing of Turbo EC fan is made of low-combustible polypropylene. The removable central unit with a motor, impeller and terminal box is attached to the fittings by means of special mounting brackets with integral latches. This helps to make the fan maintenance extremely simple and convenient. Fan service no longer requires major disassembly and dismantling of the fan: all you have to do is remove the main unit from the casing and carry out the maintenance as required. The inlet fitting has a profiled header which ensures smooth air flow into the fan. Conically shaped impelles with specially profiled blades cause circular velosity rise, that resuts in airflow boost and pressure increase comparing to conventional design. The fan outlet combination of a diffuser, specially designed impeller and rectifier allow for the optimim air distribution: high air capacity and pressure without excessive noise. |

|

| MOUNTING | |

|

The fans are intended for installation in matching diameter air ducts at any point of the ventilation system without limitation to mounting angle.The fan casing has a flat mounting plate for a secure wall mounting.Electrical connection and installation must be performed in accordance with the instruction manual and the electrical connections diagram applied to the terminal box.A single system may have several fans installed in parallel to boost the output capacity or in series to boost the working pressure. |

|

| MOTOR | |

|

High-efficient direct current EC motor. EC technology meets the up-to-date requirements to energy-saving and controllable ventilation and provides up to 35 % energy saving as compared to asynchronous motors.EC motor ensures totally controllable speed range for the fan and has integrated overheating protection with automatic restart.EC motor has no friction and wearing parts as capacitor und brushes. Instead a maintenance-free EC controller electronic circuit board is used.The impeller is dynamically balanced.The fan is compatible with 50 Hz and 60 Hz power mains and the maximum speed does not depend on power mains frequency. |

| Parameter | Turbo EC 250 | Measurement unit |

|---|---|---|

| Voltage | 230 | V |

| Phase | 1 | ˜ |

| Frequency | 50/60 | Hz |

| Current | 1.38 | A |

| Power | 169 | W |

| RPM | 2870 | min-1 |

| Maximum air flow | 1285 | m³/h |

| Maximum air flow | 357 | l/s |

| Sound pressure level at 3 m | 53 | dBА |

| Connecting piece | 250 | mm |

| Transported air temperature | -25...+55 | °С |

| Ingress protection rating | IPX4 | - |

| EC motor | yes | - |

| Weight | 7.80 | kg |

| Design | axial, centrifugal | - |

| SEC class | – | - |

| Mounting | Inline | - |

| ErP | 2018 | - |

- Selection method:

- Air capacity:

- Pressure:

- Air capacity: --

- Pressure: ---

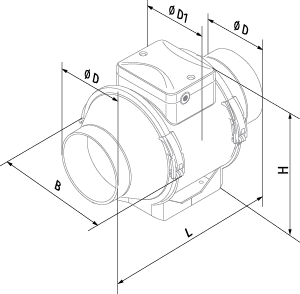

| Type | Dimensions [mm] | ||||

| ØD | ∅ D1 | B | H | L | |

| Turbo EC 250 | 247 | 257 | 288 | 339 | 383 |

| Sound power level, A-weighted | Total | Octave frequency bands [Hz] | LpA 3 m | LpA 1 m | |||||||

| 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 | ||||

| LwA to inlet [dBA] | 81 | 43 | 51 | 64 | 77 | 77 | 77 | 69 | 62 | 61 | 71 |

| LwA to outlet [dBA] | 81 | 49 | 54 | 67 | 75 | 78 | 77 | 72 | 62 | 61 | 71 |

| LwA to environment [dBA] | 73 | 53 | 49 | 56 | 66 | 71 | 68 | 55 | 43 | 53 | 63 |

| Series | Motor type | Duct diameter [mm] |

| Turbo | EC: electronically commutated motor | 100; 125; 150; 160; 200; 250; 315 |

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents