Blauberg Kamin

- Description

- Modifications

- Capacity diagram

- Downloads

- Designation key

| USE

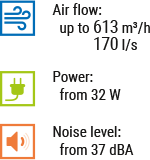

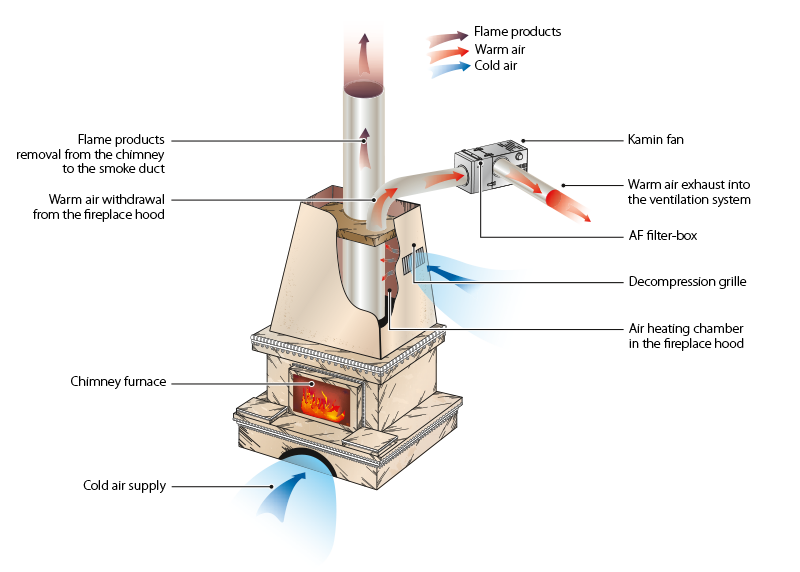

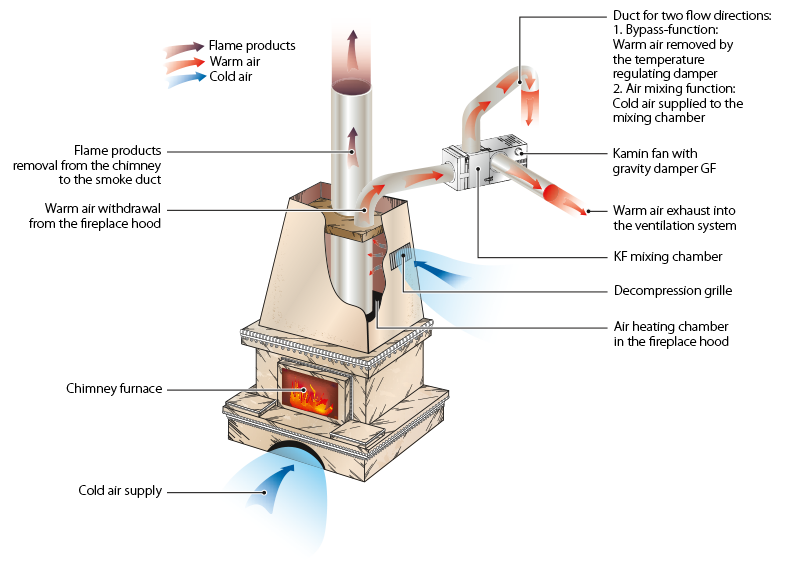

For arranging warm air distribution system from chimney room to other rooms. For heating of occasionally or seasonally occupied buildings. Operating temperature from 0 to 150 °C. Compatible with Ø 125 up to 160 mm round air ducts. DESIGNAtmospheric resistant galvanized steel casing and impeller. Thermal and heat-insulation with non-flammable mineral wool. The casing is perforated for internal air circulation for cooling the motor down. The casing has fixing for connection of extra options (filter, mixing chamber, bypass system). Power is supplied to the fan through an external terminal box with sealed electric lead-in. Switches on and off at set temperatures. Regulation by built-in temperature regulator.

Single-phase asynchronous motor. Centrifugal impeller with forward curved blades. The Kamin-ER fan is equipped with an external rotor motor. The motor is placed off the air flow and is equipped with extra axial impeller for motor cooling and blowing off. Motor insulation class F. Equipped with ball bearings for longer service life. Dynamically balanced impeller. Overheating protection by built-in thermal switches with automatic restart. SPEED CONTROLSmooth speed control with an external thyristor controller or step speed control with an external auto transformer (both available upon separate order). |

Suitable for installation in any mounting position with respect to air flow direction in the system. Warm air distribution from the fan to other premises through the mounted air ducts. OPTIONS

|

||||||||||

| OPERATION LOGIC OF THE FAN KAMIN WITH AF FILTER-BOX | |||||||||||

|

|||||||||||

| OPERATION LOGIC OF THE FAN KAMIN WITH BYPASS SYSTEM | |||||||||||

|

|||||||||||

| Modification name |

|---|

| Kamin 125 |

| Kamin 150 |

| Kamin 160 |

| Kamin-ER 125 |

| Kamin-ER 150 |

| Kamin-ER 150 max |

| Kamin-ER 160 |

| Modification name | |

|---|---|

| Kamin 125 | |

| Kamin 150 | |

| Kamin 160 | |

| Kamin-ER 125 | |

| Kamin-ER 150 | |

| Kamin-ER 150 max | |

| Kamin-ER 160 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Selection method:

- Air capacity:

- Pressure:

- Air capacity: --

- Pressure: ---

| Series | Modification | Duct diameter | Motor modification | Options |

| Kamin | _: standard -ER: external rotor motor |

125; 150; 160 | _: standard max: high-powered motor |

US: speed switch AF: metal filter-box KF: metal mixing chamber GF: gravity damper |

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents