Blauberg S-Vent

- Description

- Modifications

- Capacity diagram

- Downloads

- Designation key

- Accessories

| USE |  |

||||

|

Extract ventilation systems installed in various premises.Suitable for use as a component of an assembled air handling or conditioning unit.Compatible with Ø 140 up to 500 mm round air ducts or 125x125 up to 800x800 mm rectangular air ducts. |

|||||

| DESIGN | |||||

|

Scroll casing is made of steel and is covered with a special polymer coating.The fan is equipped with a round intake flange and exhaust rectangular flange for connection to respective air ducts.The fan casing design provides several impeller rotating positions rightwards (R) or leftwards (L) with 45° pitch angle.The casing includes mounting brackets with a mount pad for to facilitate the fan installation to an even surface. |

|||||

| MOTOR | SPEED CONTROL | ||||

|

Two-, four-, six- or eight-pole three-phase asynchronous motor with centrifugal impeller and forward curved blades.Galvanized steel impeller.Equipped with ball bearings for longer service life.Dynamically balanced impeller.IP54 ingress protection rating. |

Smooth or step-up speed control with an external auto transformer or frequency inverter (both available upon separate order). |

||||

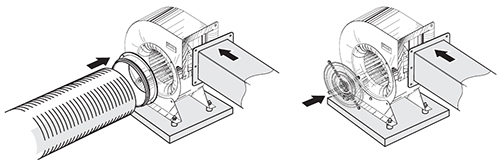

| MOUNTING | |||||

|

The fan is designed for installation as a single unit or as a component unit of ventilation chambers or air conditioning units.The fan has a connection possibility for two air ducts, a rectangular discharge air duct through the flange on the casing as well as a round intake air duct through the connecting flange FRZ-SV. Available upon separate order. In case of rectangular discharge air duct connection a discharge vent must be covered with the SG-SV grille to protect the fan from foreign object ingress. Available upon separate order.

|

The vibration isolators, either of rubber type SI-G or spring-loaded type SI-F, are recommended for noise and vibration attenuation. Vibration isolators reduce dynamic loads on the fan, enhance reliability and durability of the ventilation equipment. The vibration isolators are attached through holes in the mounting pad. Available upon separate order.

|

||||

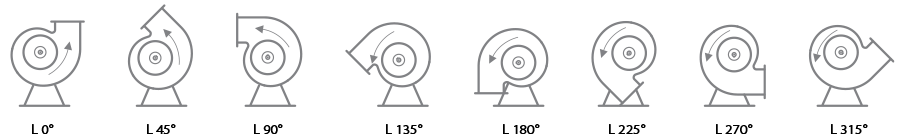

| SCROLL ORIENTATION (view on the intake side) | |||||

|

Right scroll orientation

Left scroll orientation

|

|||||

| Modification name | |

|---|---|

| S-Vent 140x74-0.25-4D | |

| S-Vent 140x74-0.37-2D | |

| S-Vent 160x74-0.55-4D | |

| S-Vent 160x74-0.75-2D | |

| S-Vent 180x74-0.55-4D | |

| S-Vent 180x74-1.1-2D | |

| S-Vent 200x93-0.55-4D | |

| S-Vent 200x93-1.1-2D | |

| S-Vent 225x103-1.1-4D | |

| S-Vent 225x103-2.2-2D | |

| S-Vent 240x114-2.2-4D | |

| S-Vent 240x114-3.0-2D | |

| S-Vent 250x127-1.5-6D | |

| S-Vent 250x127-2.2-4D | |

| S-Vent 250x127-5.5-2D | |

| S-Vent 280x127- 2.2-4D | |

| S-Vent 280x127-1.5-6D | |

| S-Vent 280x127-5.5-2D | |

| S-Vent 315x143-2.2-6D | |

| S-Vent 315x143-4.0-4D | |

| S-Vent 355x143-2.2-6D | |

| S-Vent 355x143-4.0-4D | |

| S-Vent 400x183-1.5-8D | |

| S-Vent 400x183-2.2-6D | |

| S-Vent 400x183-5.5-4D | |

| S-Vent 450x203-11.0-4D | |

| S-Vent 450x203-3.0-8D | |

| S-Vent 450x203-4.0-6D | |

| S-Vent 500x229-11.0-4D | |

| S-Vent 500x229-5.5-8D | |

| S-Vent 500x229-7.5-6D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

- Selection method:

- Air capacity:

- Pressure:

- Air capacity: --

- Pressure: ---

| Series | Impeller diameter and width [mm] | Motor power [kW] | Number of poles | Phase | Casing modification | Spiral casing pitch angle |

| S-Vent | 140x74; 160x74; 180x74; 200x93; 225x103; 240x114; 250x127; 280x127; 315x143; 355x143; 400x183; 450x203; 500x229 | 0.25; 0.37; 0.55; 0.75; 1.1; 1.5; 2.2; 3; 4; 5.5; 7.5; 11 | 2; 4; 6; 8 | E: single-phase D: three-phase |

R: Right L: Left |

0; 45; 90; 135; 180; 225; 270; 315 |

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents