Blauberg KOMFORT Roto EC D2E 350 L/R S21

EAN

EAN - Description

- Characteristics

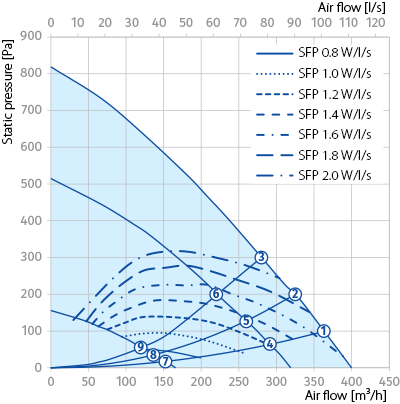

- Capacity diagram

- Downloads

- Designation key

- BIM

- Accessories

- Dimensions

- Additional characteristics

| FEATURES

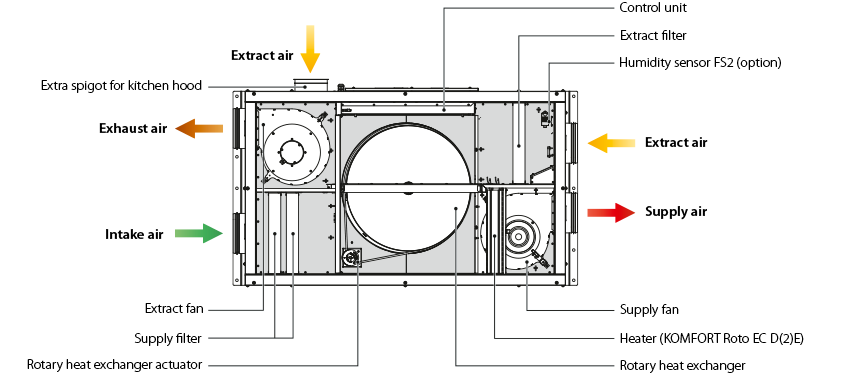

Air handling units for efficient supply and exhaust ventilation in flats, houses, cottages and other buildings. Heat recovery is provided by the rotary heat exchanger and minimizes ventilation heat losses. Controllable air exchange for creating the best suitable indoor microclimate. Compatible with round Ø 160 and 200 mm air ducts. Additional spigot for kitchen hood air duct connection. DESIGNThe fan casing is made of galvanized steel, internally filled with mineral wool layer for heat and sound insulation. The spigots are located at the sides of the unit and are rubber sealed for airtight connection to the air ducts. KOMFORT Roto EC D(2) – model without electric heater. KOMFORT Roto EC D(2)E – model with electric heater. The insulation of KOMFORT Roto EC D(E) is 40 mm, for KOMFORT Roto EC D2(E) is 20 mm. Unit maintenance is performed from the bottom panel side. The distinctive feature of KOMFORT Roto EC D2(E) is a low casing profile.

|

High-efficient external rotor EC motors and centrifugal impellers with forward curved blades are used for air supply and exhaust. EC motors have the best power consumption to air flow ratio and meet the latest demands concerning energy saving and high-efficient ventilation. EC motors are featured with high performance, low noise level and totally controllable speed range. Dynamically balanced impellers. AIR FILTRATIONTwo built-in filters with G4 and F7 filtration class provide efficient supply air filtration. Optionally, a H13 supply air filter may be used. The G4 filter is used for extract air filtration. MOUNTINGThe air handling unit is designed for suspension to a ceiling, wall mounting or mounting to a horizontal plane. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| KOMFORT ROTO EC D(E) R (RIGHT SERVICE SIDE) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

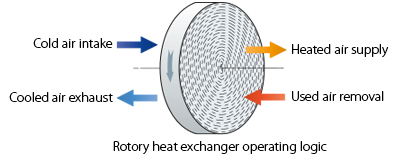

| KITCHEN HOOD

All the models are equipped with a fifth spigot for connection of the air duct from the kitchen hood. ROTARY HEAT EXCHANGERThe unit has a high-efficient rotary aluminium heat exchanger. The rotary heat exchanger is a short, rotating cylinder, filled with corrugated aluminium sheet layers. The air streams flow through them. The band layers of the heat exchanger first come in contact with the supply and then with extract air flows. Therefore the band is alternatively warmed up and cooled down and the extract air heat and humidity are transferred to the cold intake air. This way heat recovery reduces heat losses in the cold season and reduces operation load for air conditioner in the warm season. The advantages of the rotary heat exchanger as compared to the plate heat exchangers include no condensate generation, maintaining comfort air humidity and high freeze resistance.

|

HEATER

The KOMFORT Roto EC D(2)E units are equipped with the electric heater. If the necessary temperature level of the supply air cannot be achieved through heat recovery, the heater turns on automatically and heats the air supplied to the premise. The heaters incorporate protective measures securing the safe unit operation. CONTROL AND AUTOMATIONKOMFORT EC D… S21 units are equipped with an integrated automation system. The remote control panel is not included in the delivery set (purchased separately). The S21 controller allows integrating the unit into the Smart Home system or BMS (Building Management System). The unit can be controlled via the Blauberg AHU mobile application via Wi-Fi.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||

| AUTOMATION FUNCTIONS | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Parameter | KOMFORT Roto EC D2E 350 L/R S21 | Measurement unit |

|---|---|---|

| Voltage | 230 | V |

| Phase | 1 | ˜ |

| Frequency | 50/60 | Hz |

| Max. unit power | 1600 | W |

| Max. power without electric heater | 200 | W |

| Reheater power consumption | 1400 | W |

| Max. unit current without electric heater | 1.3 | A |

| Max. unit current | 6.9 | A |

| Electric heater current | 5.6 | A |

| RPM | 3200 | min-1 |

| Maximum air flow | 111 | l/s |

| Maximum air flow | 400 | m³/h |

| Sound pressure level at 3 m | 33 | dBА |

| Insulation | 20 mm mineral wool | mm |

| Transported air temperature | -25...+40 | °С |

| Extract filter | G4 | - |

| Supply filter | G4, F7 (Option: H13) | - |

| Heat recovery efficiency | 73–87 | % |

| EC motor | yes | - |

| Heat exchanger type | rotary | - |

| Heat exchanger material | aluminum | - |

| Connected air duct diameter | 160 | mm |

| Weight | 79 | kg |

| Casing material | galvanized steel | - |

| Outdoor mounting | no | - |

| SEC class | A | - |

| Mounting | ceiling mounting, wall mounting | - |

| ErP | 2016, 2018 | - |

| * | Heat recovery efficiency is specified in compliance with EN 13141-7. | - |

- Selection method:

- Air capacity:

- Pressure:

- Air capacity: --

- Pressure: ---

| Series | Unit type | Motor type | Mounting type | Modification | Heater type | Rated air flow [m³/h] | Service side | Control |

| KOMFORT | Roto: rotary heat exchanger | EC: electronically commutated motor | D: suspended mounting, horizontally directed spigots | _: standard (insulation 40 mm) 2: low-profile (insulation 20 mm) |

_: no heater E: electric heater |

250; 350; 650 | L: left R: right |

S21 |

| KOMFORT Roto EC D2E 350 L/R S21 | ||

| G4 panel filter | FP 372x180x48 G4 | |

| F7 panel filter | FP 372x180x48 F7 | |

| H13 panel filter | FP 372x180x48 H13 | |

| Control panel | S22 | |

| Wireless control panel | S22 Wi-Fi | |

| LCD Control panel |  |

S25 |

| VOC sensor | DPWQ30600 | |

| External CO2 sensor | DPWQ40200 | |

| Humidity sensor |  |

DPWC11200 |

| Humidity sensor | HR-S | |

| Humidity sensor | FS2 | |

| Kitchen hood |  |

DAH 251-13 |

| Backdraft air damper | VRV 160 | |

| Air damper |  |

VKA 160 |

| Electric actuator | LF230 | |

| Electric actuator | TF230 | |

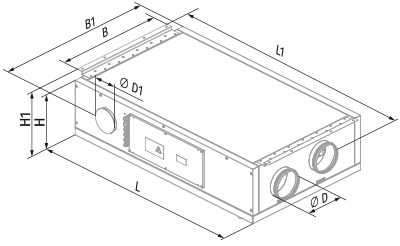

| Model | Overall dimensions [mm] | |||||||

| D | D1 | B | B1 | H | H1 | L | L1 | |

| KOMFORT Roto EC D2E 350 L/R S21 | 160 | 125 | 798 | 847 | 225 | 245 | 1362 | 1457 |

|

|

| Sound power level, A-weighted | Total | Octave frequency band [Hz] | LpA 3 m | LpA 1 m | |||||||

| 63 | 125 | 250 | 500 | 1000 | 2000 | 4000 | 8000 | ||||

| LwA to supply inlet [dBA] | 59 | 26 | 45 | 53 | 54 | 52 | 48 | 43 | 34 | ||

| LwA to supply outlet [dBA] | 83 | 44 | 58 | 67 | 75 | 75 | 79 | 75 | 71 | ||

| LwA to exhaust inlet [dBA] | 54 | 25 | 40 | 50 | 50 | 43 | 41 | 38 | 30 | ||

| LwA to exhaust outlet [dBA] | 74 | 42 | 52 | 63 | 70 | 63 | 68 | 66 | 62 | ||

| LwA to environment [dBA] | 53 | 18 | 35 | 46 | 49 | 48 | 43 | 37 | 33 | 33 | 43 |

Data provided for point 1 of the air flow diagram

Calculation of air temperature downstream of the heat exchanger:

t = toutd + khr × (textr - toutd) / 100,

where toutd – outdoor air temperature [°C] textr – extract air temperature [°C] khr – heat exchanger efficiency (according to the diagram) [%]

Domestic fans

Domestic fans Industrial fans

Industrial fans Single-room air handling units with heat recovery

Single-room air handling units with heat recovery Air handling units

Air handling units  Smoke extraction and ventilation

Smoke extraction and ventilation Ventilation accessories

Ventilation accessories Ventilation ducts and fittings

Ventilation ducts and fittings Air distribution

Air distribution Measurement and control technology

Measurement and control technology Ventilation sets and vents

Ventilation sets and vents